Z-FIX Computer head + Z-FIX Main pole + optional laser and laser receiver.

Z-FIX is a versatile solution that is compatible with lasers and laser receivers from a wide range of brands. Whether you use equipment from Spectra, Leica, Topcon, Hilti, Geofennel, Geomax, Bosch, Nedo or other manufacturers, you can be sure that Z-FIX will work seamlessly with them. This flexibility makes Z-FIX an excellent choice for professional users who need reliable and compatible equipment for their surveying and construction projects.

Z-FIX consists of a "Main rod" and a "Computer head". The computer head is threaded onto the rod which can then be moved up/down. At the bottom of the computer head there is a removable bracket where the laser receiver is screwed on.

As usual, you set up your laser in a suitable location where you have access to a benchmark with a known elevation. Place the rod over the known point and move the computer head so that the laser receiver ends up in the laser plane. Then you enter the height of the benchmark into the computer head and Z-FIX is ready to use. When the establishment is complete, the height shown in the display will always be the height you have at the bottom of the rod. (Z-FIX is brand-independent, so the choice of laser is up to the user).

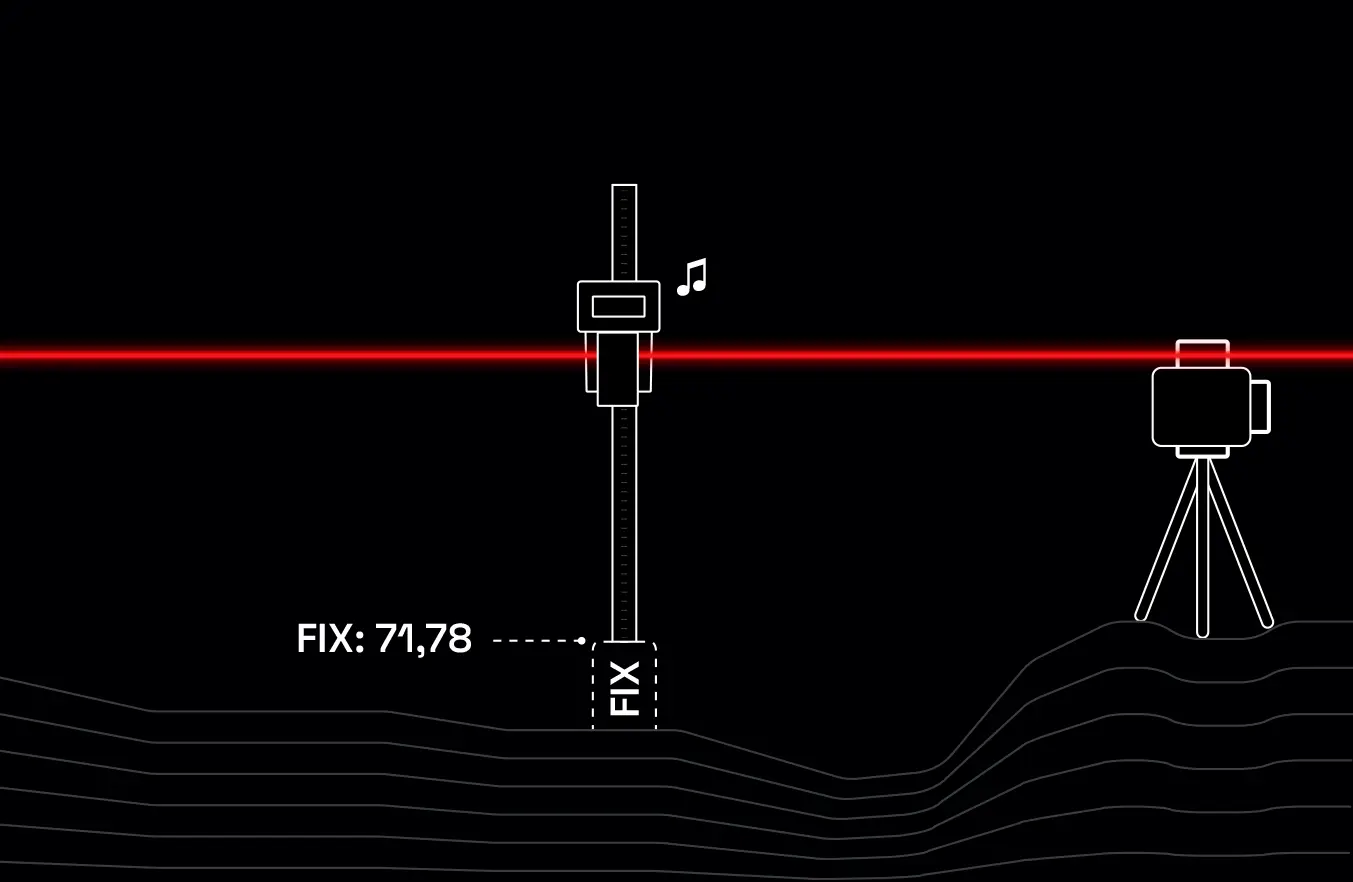

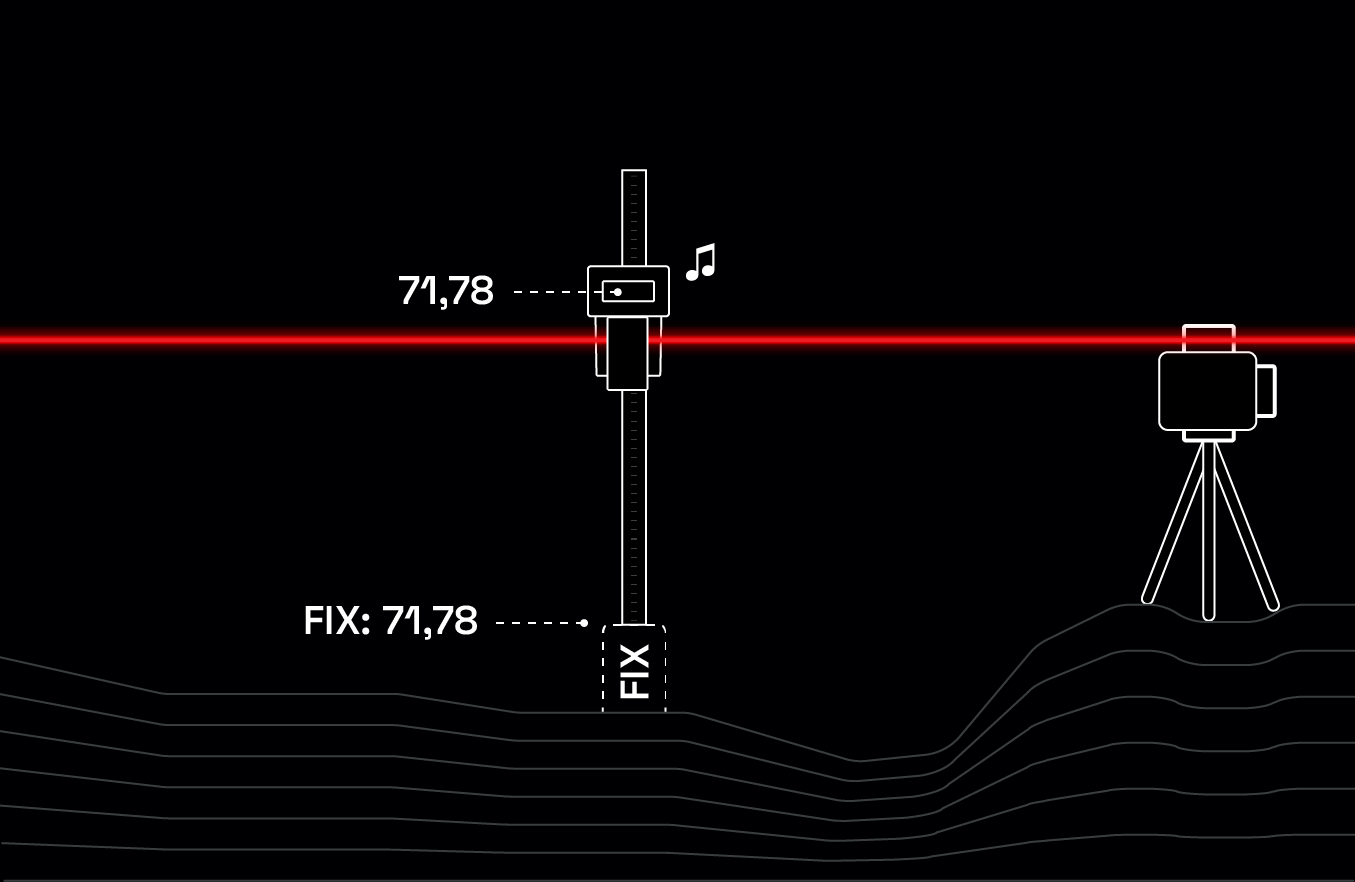

Place the Z-FIX on a benchmark, i.e. a specific height above sea level.

Move the Z-FIX Computer Head with the laser receiver until the laser receiver is leveled with the laser and signals you.

Lock the computer head.

Program the known elevation of the benchmark 71.78 meters above sea level into the computer head.

When the known elevation is programmed, Z-FIX is ready for use.

Now the display always shows the height above sea level that you have at the bottom of the rod (when the laser receiver is at the right level with the laser and giving a signal).

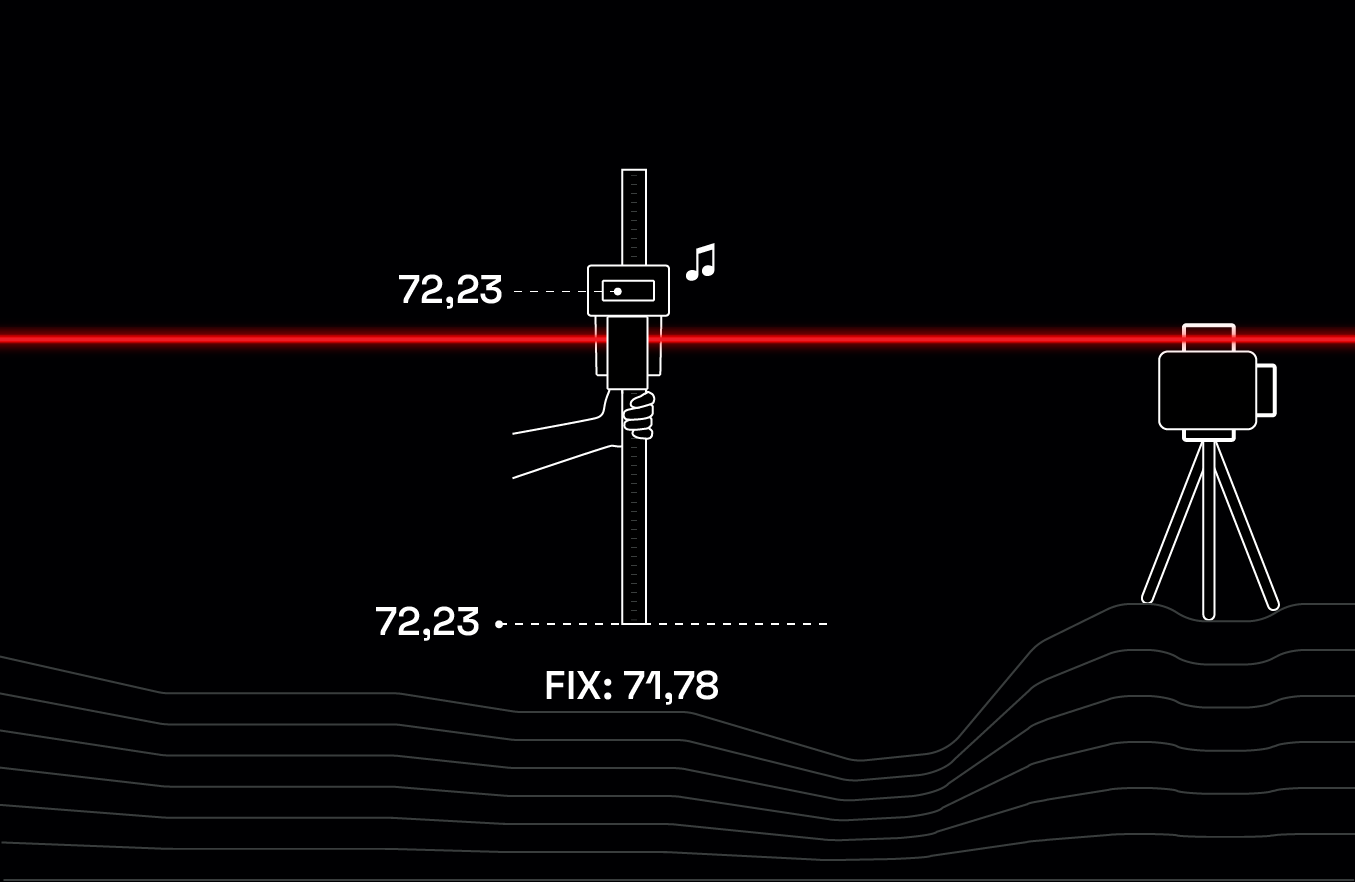

Assume you want to stake out the height for "Finished Floor", 72.23 meters above sea level.

Move the Z-FIX computer along the rod...

...until the desired height 72.23 is shown in the display.

Lock the computer head in place on the rod.

Lift the rod.

When the laser receiver gives a signal, you have the desired height of 72.23 meters above sea level, at the bottom of the pole.

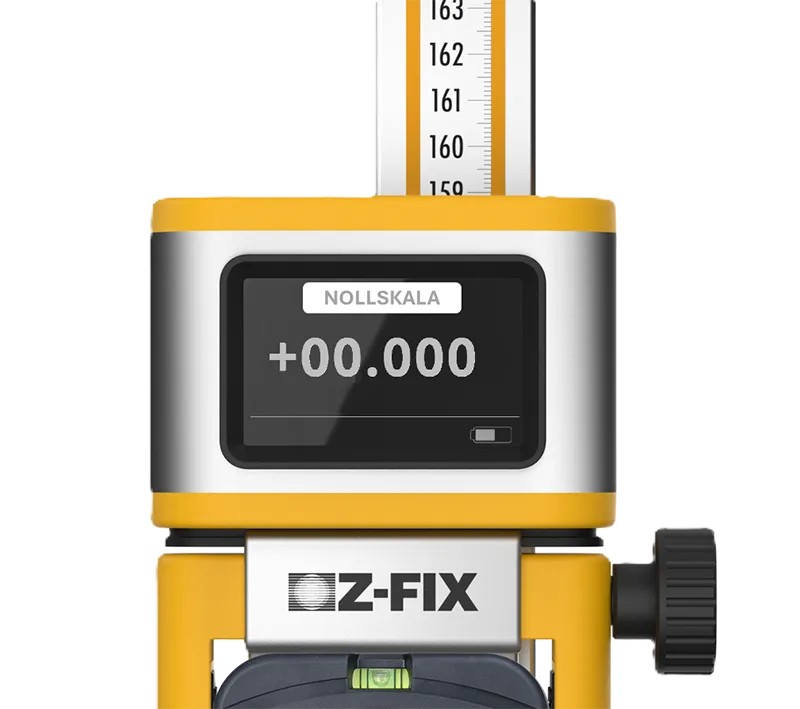

Z-FIX Computer Head

The computer head body is made of durable plastic and aluminum. Inside you will find electronics with the latest technology.

Push buttons

Functional keypad with lighting. Positioned for smooth programming and easy operation.

Display

Large and clear backlit 2.7” LCD display. In front of the display is a protective glass and a bumper.

Locking screws

At the back of the computer head is a locking knob for locking against the rod. On the universal mount is a similar one for locking the laser receiver.

Universal clamp mount

Z-FIX is equipped with a universal mount to accommodate the different types of laser receivers on the market.

Battery cover

The battery cover is located under the universal clamp bracket. Slide the bracket to the side in the direction of the locking knob. The battery cover screws are “captive” so there is no risk of them getting lost.

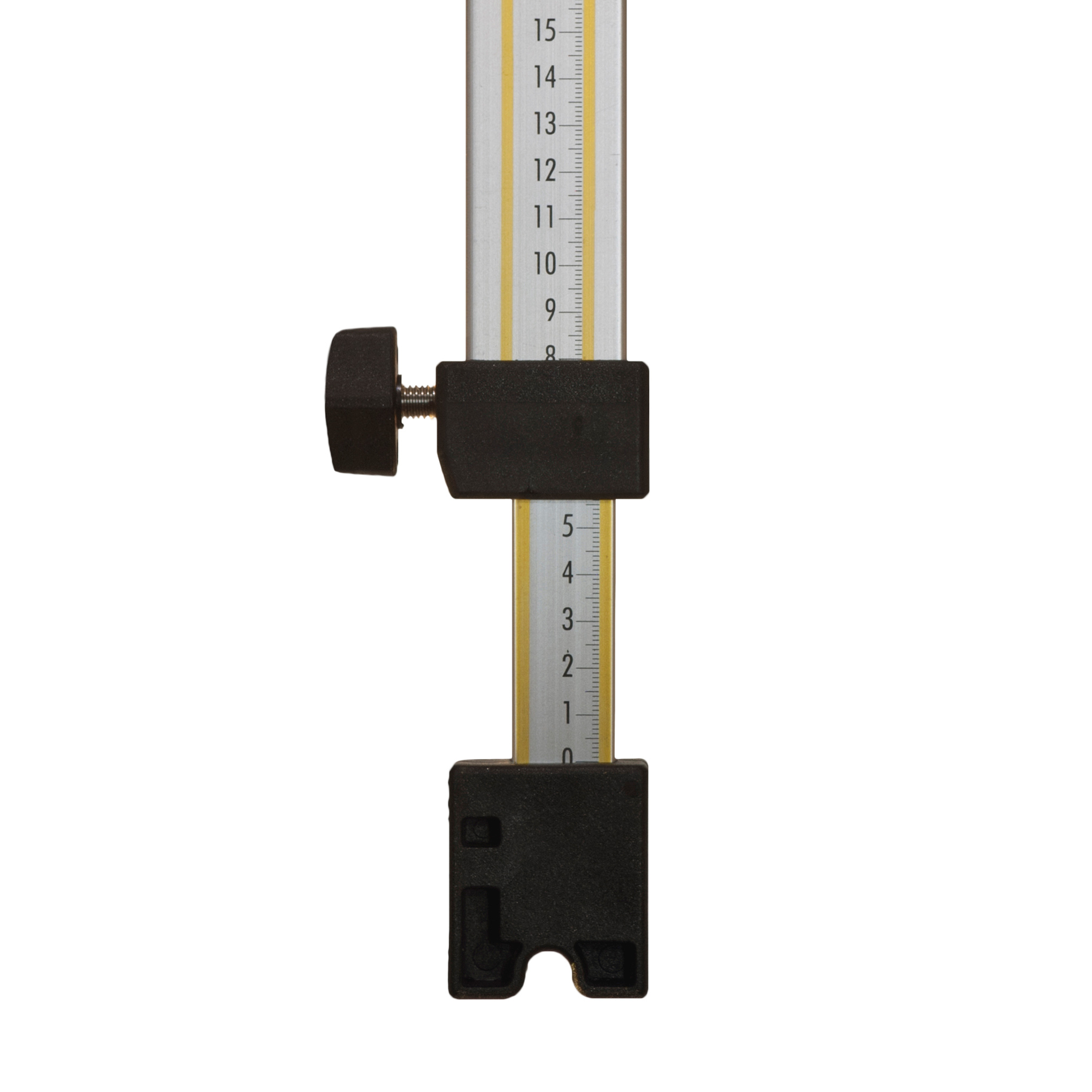

Main rod

Specially milled anodized aluminum profile with a measuring height of 2.21 m, total length 2282 mm. The main rod is available as both fixed and divisible.

Telescopic rod

Anodized aluminum profile that is built into the main rod. The extendable length is 1 m for the divisible main rod and 2 m on the fixed main rod.

Scales on the rods

6 different measuring scales, printed in the layer with clear colors and different functions.

Z-FIX Computer Head

The computer head body is made of durable plastic and aluminum. Inside you will find electronics with the latest technology.

Push buttons

Functional keypad with lighting. Positioned for smooth programming and easy operation.

Display

Large and clear backlit 2.7” LCD display. In front of the display is a protective glass and a bumper.

Locking screws

At the back of the computer head is a locking knob for locking against the rod. On the universal mount is a similar one for locking the laser receiver.

Universal clamp mount

Z-FIX is equipped with a universal mount to accommodate the different types of laser receivers on the market.

Battery cover

The battery cover is located under the universal clamp bracket. Slide the bracket to the side in the direction of the locking knob. The battery cover screws are “captive” so there is no risk of them getting lost.

Main rod

Specially milled anodized aluminum profile with a measuring height of 2.21 m, total length 2282 mm. The main rod is available as both fixed and divisible.

Telescopic rod

Anodized aluminum profile that is built into the main rod. The extendable length is 1 m for the divisible main rod and 2 m on the fixed main rod.

Scales on the rods

6 different measuring scales, printed in the layer with clear colors and different functions.

In addition to the basic function of displaying plus heights in Elevation Mode, there is also an Offset Mode in Z-FIX.

The Offset Mode works in parallel with the Elevation Mode and offers the possibility of zeroing any plus height, i.e. as an offset to the selected height.

After zeroing, the display shows + or – values in relation to the zeroed starting height.

But with the Offset Mode, you can, for example, measure how much to excavate or fill in relation to the selected plus height that you have zeroed.

Or you can simply use the Offset function to measure height differences between different points.

You can easily switch between the two programs with the press of a button.

Being able to get the plus heights at the bottom of the pole, in such a safe and easy way as Z-FIX offers, is of course very meritorious. But often you want to "add" for the possible superstructure afterwards.

For example, it may be that the plus height applies to the finished floor and that you want to excavate 35 cm below it.

This is easily solved with the built-in telescopic pole that you can pull out downwards depending on how much you want to be below the selected plus height. Superb!

If instead you excavate for e.g. a flat surface, road, green area etc. with different plus heights, but with the same superstructure, you simply leave the extended telescopic pole at the same extended dimensions that you want to be below the finished plus height and only adjust the Z-FIX computer head to the different plus heights on the finished surface. Simple and easy!

On the back of the telescopic pole there is something called a red sectioning scale, which is used for sectioning with large height differences.

Website created by Area81.se